16. bis 17. September 2025, Messe Luzern

AM Expo

Fachmesse und Symposium: Inspiration, Weiterbildung und Netzwerk

Bis zur nächsten AM Expo nichts verpassen!

Bis zur nächsten AM Expo nichts aus der Branche verpassen: Auf Additively publizieren führende Anbieter aus der additiven Fertigung ihre Neuheiten, Videos, Fachwissen, Veranstaltungen und vieles mehr.

Die AM Expo ist die einzige Fachmesse in der Schweiz, die sich ausschliesslich mit additiver Fertigung beschäftigt. 80 Aussteller entlang der gesamten Wertschöpfungskette zeigen an der Fachmesse anwendungsorientiert auf, welche Möglichkeiten die additive Fertigung bietet und wie die Fertigungstechnologie rentabel eingesetzt werden kann.

Ob Einsteiger oder Profi im Bereich der additiven Fertigung: Die AM Expo gibt kompetent Antwort auf zentrale Fragen zur additiven Fertigung, abgestimmt auf die verschiedenen Anwendungsbereiche.

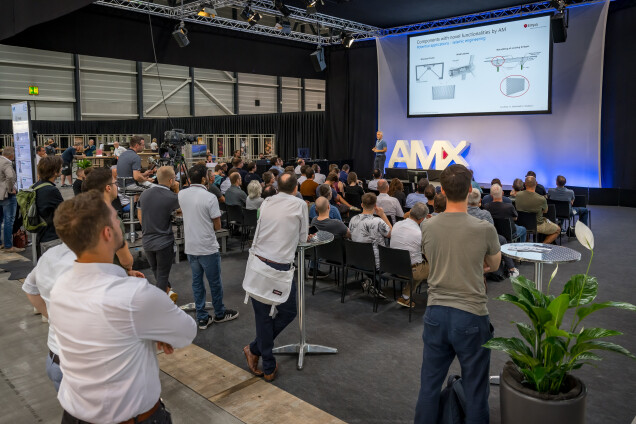

Erfolgreiche Messe

Die AM Expo ist nach zwei gelungenen Messetagen zu Ende gegangen. Das Interesse an der Fachmesse für additive Fertigung war sehr gross. Die Organisatoren zeigen sich höchst zufrieden.

Impressionen

Die AM Expo bot während zwei Tagen Inspiration, Fachwissen und Netzwerk. Tauchen Sie mit den Impressionen nochmals ein in die AM Expo 2023.

AM Expo 2025

Save the date: Die nächste AM Expo findet vom 16. bis 17. September 2025 bei der Messe Luzern statt.

Bleiben Sie vernetzt!

Sie möchten 365 Tage im Jahr auf dem Laufenden bleiben rund um die additive Fertigung? Kein Problem! Auf Additively publizieren führende Unternehmen rund um die additive Fertigung Neuheiten, Videos, Fachwissen, Veranstaltungen und vieles mehr. Lassen Sie sich inspirieren...